Comprehensive CNC Service & Manufacturing Maintenance Solutions

Experience unparalleled manufacturing maintenance support with our world-class team, dedicated to delivering exceptional results without compromise. Our best-in-class customer service, expertise, and methodology ensure your machine downtime is minimized, and production efficiency is maximized.

Electrical, Mechanical, and Machine Tool Services

Our specialized technicians excel in troubleshooting and repairing machine failures and quality issues, with expertise in FANUC Controls (all models). We also source, repair, or fabricate specialty or obsolete components, catering to diverse industries such as machine tool, grinding, food processing, pharmaceutical, packaging, heat treatment, assembly, and more.

Project Planning and Repair

Our expert teams plan and execute projects efficiently, ensuring timely completion and minimizing production disruptions.

CNC / Machine Tool Health Assessments and Diagnostics

Our comprehensive assessments and diagnostic services include:

- CNC troubleshooting (FANUC Controls – all models)

- CNC Alarm diagnosis and repair

- FANUC Robots

- Electrical schematics/ladder troubleshooting

- Geometric accuracy inspection

- Ballbar analysis

- Oil analysis

- Interferometer laser profile

- Vibration analysis

- Spindle health check

- Electronic monitoring

- Electronic levels

- Visual inspection

- Operator interviews

- Thermography study

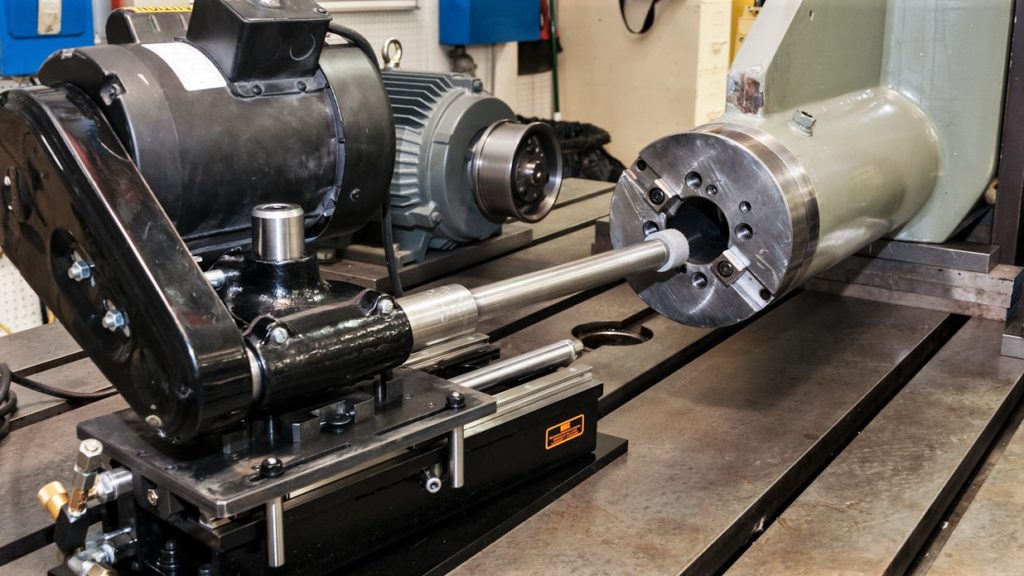

Rebuilds and Refurbishments

We refurbish your machines to like-new specifications, specializing in a wide range of rebuilds and repairs, including spindles, turcite replacement, linear guide rails, ball screw replacement, rotary axes, ATC, and APC. Our spindle and gearbox rebuild/repair services include initial to final evaluation, with improvement recommendations provided.

Trust our expertise to optimize your manufacturing efficiency and minimize downtime.